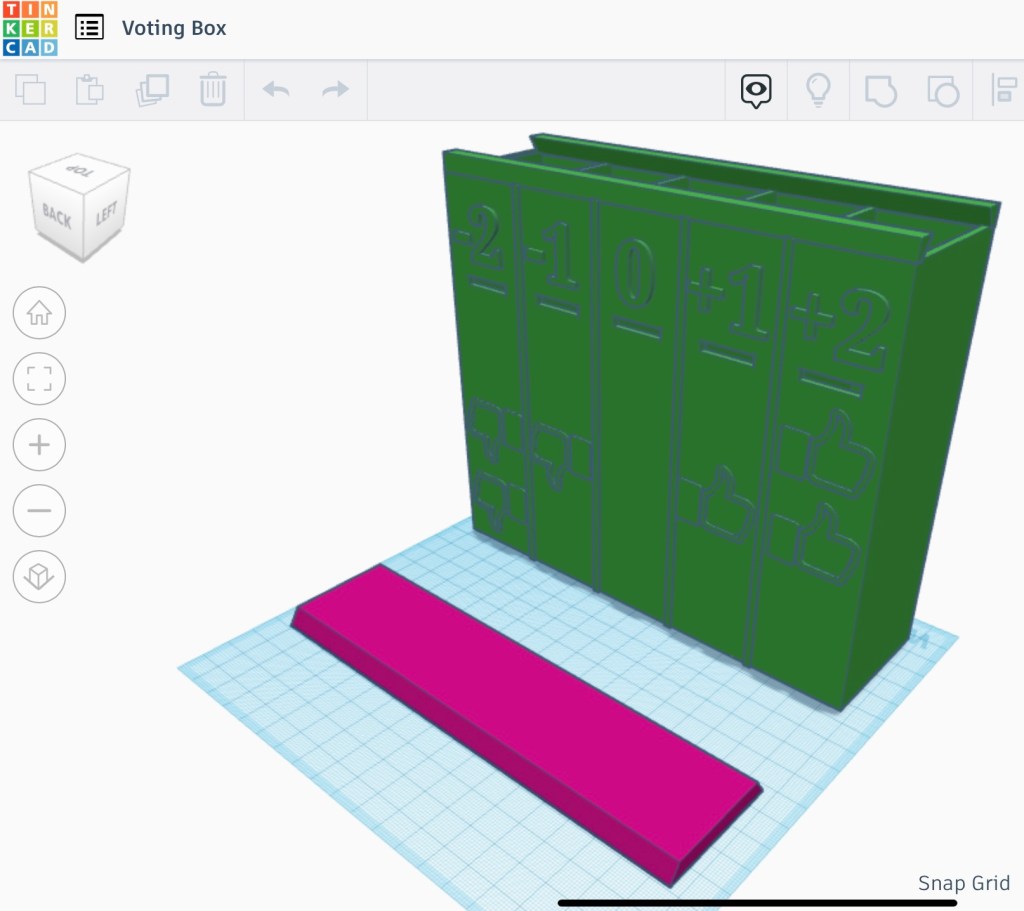

Three months ago, I designed a 3D “voting box” in Tinkercad to be used at our Spring Math Festivals. The beveled cover would slide on top, sealing the box. The idea was to have attendees answer the prompt “How do you feel about math after attending today’s event?” As you can see in the design below, the choice of response ranged from two thumbs down to two thumbs up. Every participant, from preschooler to grandparent, would be given a ticket to deposit in the box upon exiting the festival. At least that was the plan.

The design was simple enough. Printing the box would take time but shouldn’t be a challenge. After the first layer was deposited, I left my printer to do it’s thing while I worked downstairs for a few hours.

Long story short—melted filament formed a big, ugly blob around the printhead. Critical wires connected to the hot end got detached. I could not heat the unit to gently remove the plastic blob without further damage. I would have to replace the entire hot end of the extruder. The parts would not arrive until after the festival.

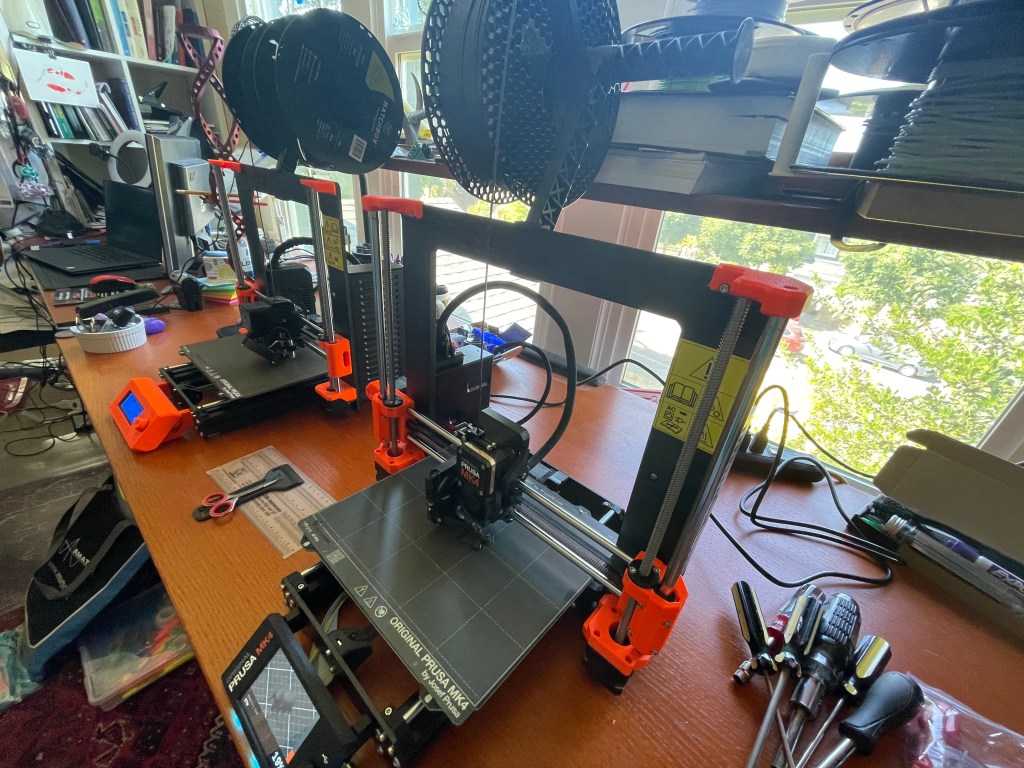

My printer is a four year old Prusa i3 MK3S. I built it myself, so intellectually I knew I should be able to handle the repairs. Yet, I was surprisingly nervous about it.

My husband sensed by concern and asked “why don’t you get the newest model instead?”

I had already bought the parts. They would arrive in a week. But I looked at the specs for the MK4 and decided to take the plunge. Worst case scenario—I’d have a brand new 3D printer to play with. Best case scenario—I’d have two working printers.

After the parts arrived it took two more weeks before I found the time to work on repairs. The internet is a wonderful source of information. Online I found step-by-step instructions (including videos) and I managed to replace the hot end in a couple of hours. I had a working printer again. The Spring Math Festivals were done so I didn’t see the need to print the voting box, but I did print medallions for 2023 Math Award Winners.

Earlier this week, my new printer arrived. Today I cleaned my work area and set the two printers side-by-side.

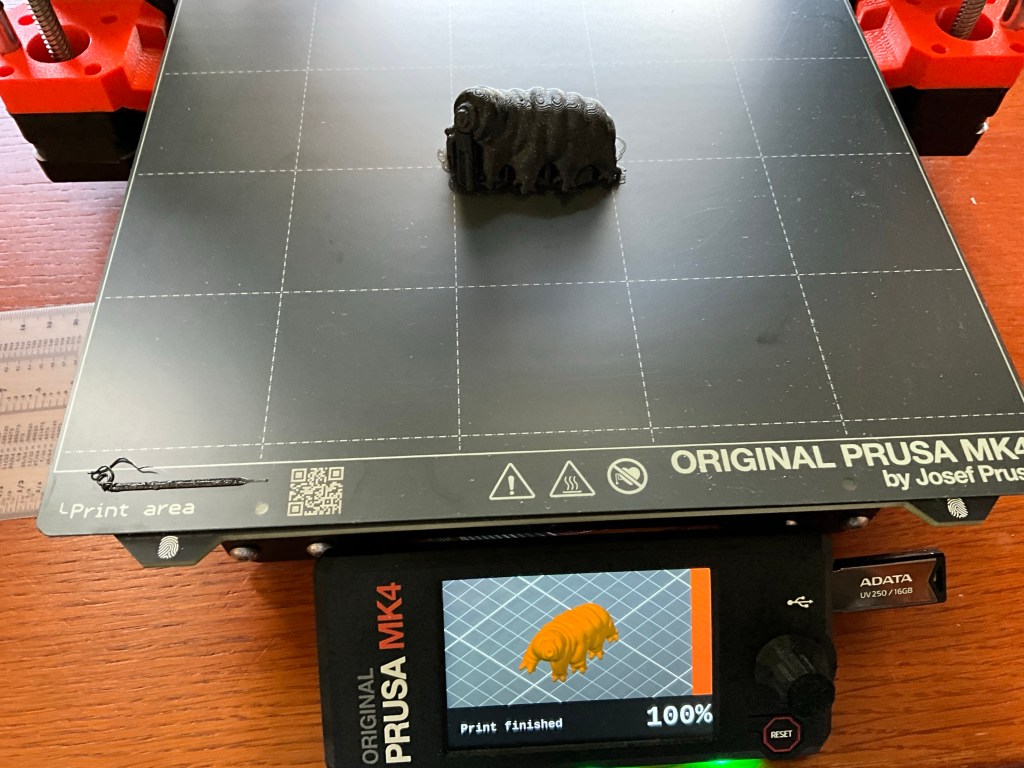

Time to put them to the test. I printed the same tardigrade model on each. The quality was similar but there was slight stringing on the MK3S print. The MK4 was 22% faster.

To determine whether the stringiness was a consequence of the printer or the filament, I exchanged filaments between printers and produced the same model again.

Conclusion: It was the filament. (Although the MK4 had fewer stringing with the ultra black than the MK3S.)

So now I have dueling printers. It’s all very exciting. I even plan to go back and print the voting box design. (As this is a story about 3D printers rather than the specific voting box, suffice it to say that I made a replacement with a cardboard box. It worked OK but was not nearly as slick as the original design.)